Ensuring Warmth with Peace of Mind: The Importance of a Gas Furnace Safety Inspection

Introduction

As the crisp winds of winter approach, our reliance on the trusty gas furnace intensifies, becoming the silent guardian that keeps our homes warm and cozy. Yet, in the pursuit of comfort, it's easy to overlook a crucial aspect—safety. A gas furnace, though efficient, requires regular check-ups to ensure it not only provides warmth but does so without posing any potential hazards.

Join us on a journey through the realm of gas furnace safety inspections, where we uncover the hidden dangers that may lurk within the heart of your home's heating system. From understanding the essential components of a gas furnace to grasping the significance of routine inspections, we'll guide you toward a winter season filled with warmth and peace of mind.

In this blog series, we'll explore the intricacies of gas furnace safety, sharing valuable insights and practical tips that empower you to safeguard your home and loved ones. Discover the telltale signs that your furnace might need attention, learn about the potential risks associated with neglecting regular inspections, and gain a deeper understanding of the preventive measures you can take to keep your heating system running smoothly.

As we delve into the world of gas furnace safety, our goal is to equip you with the knowledge to make informed decisions about the maintenance and care of your home's heating system. After all, a warm and secure home is not just a luxury—it's a necessity, and ensuring the safety of your gas furnace is the first step toward achieving that comfort with confidence.

So, grab a cup of hot cocoa, settle into your favorite reading nook, and let's embark on a journey to discover the keys to a safe and warm winter season.

The importance of getting a furnace inspection

Safety

When a gas furnace is damaged, malfunctioning, or improperly installed, it can present a very real safety hazard. After all, gas furnaces are complex heating systems that work by combusting natural gas to heat the air.

Any time you have fuel burning in a controlled environment like that, there are inherent risks if something goes wrong. For this reason, it's important to keep up with regular furnace maintenance and have your natural gas furnace inspected regularly. That way, you can not only keep the appliance running smoothly and efficiently, but you can also ensure that there aren't any serious risks to your family's safety.

What to check during a furnace inspection

During these important furnace inspections, several components and parts of the system should always be checked for proper operation. With this checklist, you can greatly reduce the risk of hazards such as fires, electrocution, and carbon monoxide leaks.

Ideally, it would help if you had a local HVAC technician conduct one of these gas furnace safety inspections at least once per year. That way, if any problem has arisen, you'll give yourself the best possible chance of catching it before it turns into a serious or dangerous situation.

Getting a new furnace installed

It's important to use a licensed heating and air conditioning contractor if you are installing a new furnace. Some several local codes and regulations must be followed. Additionally, newer furnaces have complex control systems that must be set up properly to achieve maximum efficiency from the unit.

Furnace Inspection Checklist

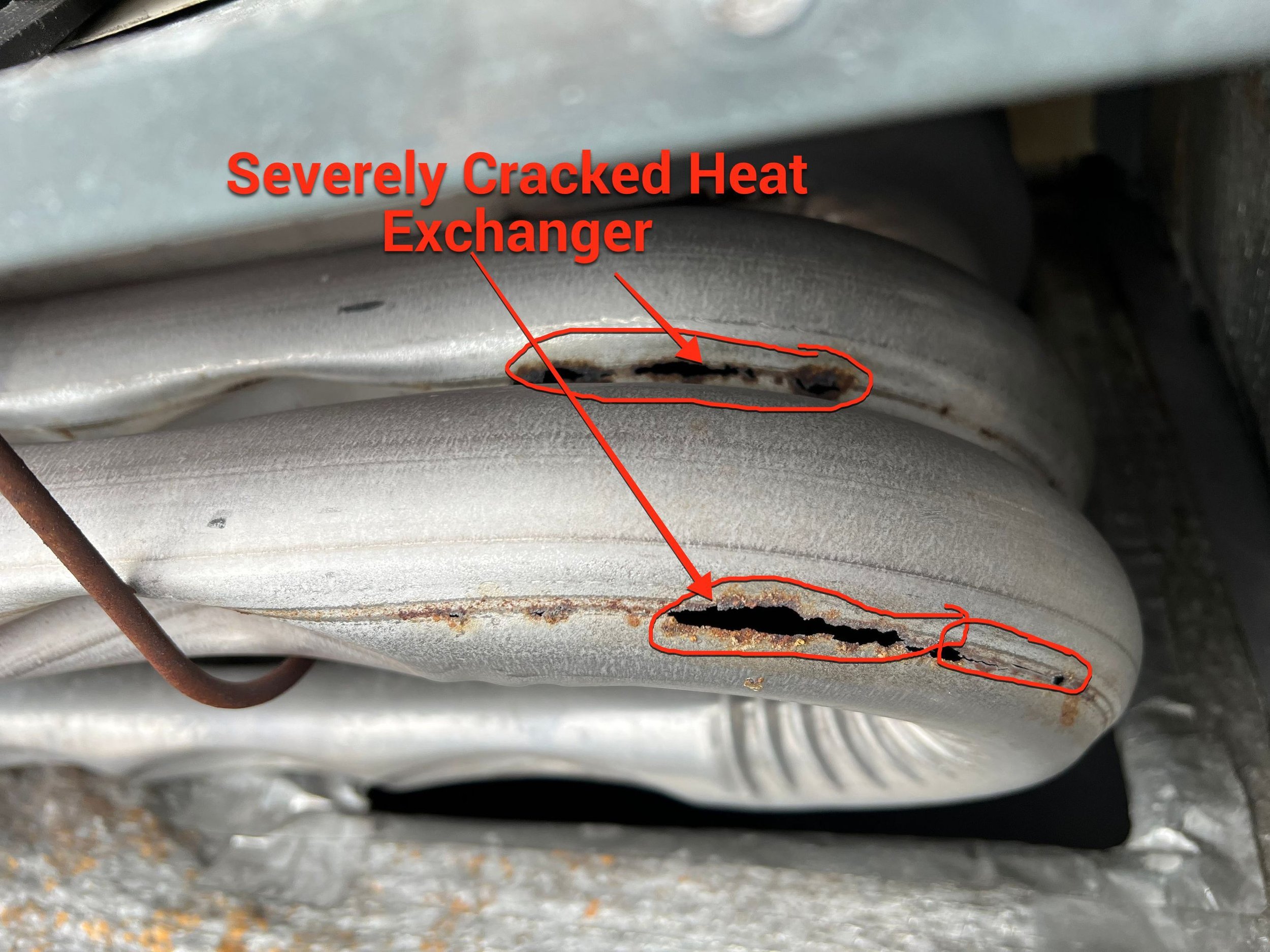

#1: Furnace Heat Exchanger

One of the most important components of any gas furnace is the heat exchanger. The heat exchanger is where the natural gas is continuously combusted to warm up the air in your home and keep your living space comfortable.

While that combustion process is occurring, the heat exchanger frequently expands and contracts. As a result, it's common for this important component to become cracked or start deteriorating. Having a cracked heat exchanger is a very serious issue and a potential safety hazard.

Furnace Safety Concerns

When the heat exchanger is cracked or otherwise damaged, it can cause carbon monoxide leaks in the home. It can also lead to other dangerous gas leaks and exhaust fumes escaping the appliance. For these reasons, checking the status of the heat exchanger should be a major part of every furnace inspection checklist.

It's also always a wise choice to have a working carbon monoxide detector if you're using a gas furnace in your home. If you ever have reason to suspect that your heating system has a cracked heat exchanger, you should immediately shut it off until you can have it handled by a professional HVAC technician.

#2: Furnace Ignitor

Older furnaces used a pilot light to light the furnace when the thermostat called for heating. Every year before the temperatures dropped, you might have noticed your parents light the pilot light in the Furnace.

Today, a furnace ignitor is used instead of the open flame of the pilot light in most furnaces. Without the ignitor, the burner won't light and your furnace will not make hot air. It's an important part of your furnace system and a common reason that your Furnace doesn't work correctly.

How the Furnace ignitor works

You might have heard the "click" from your Furnace when the thermostat calls for heating. The thermostat communicates with the ignition system causing the ignitor to create a spark or hot surface that "ignites" the gas connected to your heater. Other types of ignitors light the furnace without a spark. Instead, these ignitors get hot to light the gas in the burner.

Don't worry—a bad ignitor is a fairly common problem and the repair is typically uneventful. You can replace the ignitor without replacing the whole Furnace. Ignitors last about seven years.

#3: Furnace Flue Pipe or Vent

The flue pipe has a major role in preventing problems such as carbon monoxide leaks and exhaust fumes escaping during a gas furnace's operation. After the gas combustion process takes place within the heat exchanger, those dangerous fumes must exit the house through the flue pipe.

However, the flue pipe can become cracked or corroded, and that can create a major furnace safety issue. Specifically, when there's a problem with the flue pipe, those hazardous fumes can end up inside your living space, which can lead to carbon monoxide poisoning, brain damage, and other health problems.

Flue Material

For proper ventilation, the pipe must be in good condition. Flue pipes are made of galvanized sheet metal. Energy efficient, 90% or greater, furnaces will have flue made from PVC. The location of the furnace cabinet will also determine the type of flue pipe that's installed.

When you have your furnace checked by an HVAC technician, they must inspect the flue pipe for any signs of cracks, corrosion, loose connections, or other damage. Additionally, the furnace inspection should include verifying that nothing is obstructing the pipe. In some cases, birds can build their nests inside these flue pipes, which can obstruct airflow and even cause a fire hazard.

#4: Furnace Gas Burners

Any thorough gas furnace inspection should involve checking and cleaning the gas burners. These burners are integral for the process of fuel combustion and keeping the heating system operating properly.

Why burners need to be cleaned

Over time, though, it's inevitable for things like dirt, soot, and random debris to accumulate on these burners. That can cause the fuel to burn at lower temperatures, which will reduce efficiency as well as the overall performance of the appliance. To prevent these issues, it's important for the HVAC technician to thoroughly clean the burners.

The safety inspection checklist should also include verifying that the burners are operating properly. If they aren't combusting the fuel as they should, that gas can leak into your home, which can be a serious safety issue.

#5: Furnace Air Filters

For a furnace to continue operating smoothly, efficiently, and safely, its air filters must remain clean and unobstructed. These filters have the thankless duty of catching all of those pesky airborne contaminants, such as dust, dander, mold spores, and pollen before they can get cycled into the furnace and the air you're breathing. However, those air filters can only trap so many particles before they become clogged, and clogged filters can cause a variety of problems for the heating system.

Clogged filters

For one thing, when a furnace air filter becomes obstructed with contaminants, it can worsen the heating performance and increase the energy bills. However, that isn't all; clogged filters can prevent a safety hazard as well. The harder it becomes for the furnace to pull air through the filter, the more the airflow will become restricted. Restricted airflow can cause the system to overheat and shut down.

Unfiltered air

We come across very many homes and heating units where no filters are installed at all. This can easily create big safety problems for your furnace. Dust can quickly build up in your blower housing, cooling coils, heat exchangers, etc. This dust and debris are highly flammable and can quickly cause a fire.

In worst-case scenarios, these filters being clogged can even result in carbon monoxide leaks. However, as long as the filters are replaced regularly, your energy costs will stay in check, your home will stay comfortable, and your furnace will continue operating safely. So, during the annual inspection, your hired HVAC technician will want to ensure that the filters are clean and in good condition.

#6: Furnace Flame Sensor

The furnace's flame sensor is another component that plays a major role in keeping you safe. This sensor is designed to ensure that the system's gas valve is only opening when the flames are burning. However, if the sensor is malfunctioning, the gas valve may be open when it shouldn't, and that can create a fire hazard or lead to large amounts of toxic gas accumulating and leaking into your home.

A problem with this sensor can also affect your energy usage or the heating performance of the appliance. The sensor is very easy to replace. During thorough furnace safety inspections, a trained HVAC professional will always make a point to verify the condition and operation of the sensor.

#7: Carbon Monoxide Detectors and Furnace Safety

As you can see, there are a variety of potential gas furnace problems that can result in carbon monoxide (CO) leaks. CO is extremely dangerous, and the fact that it's colorless and odorless makes it even more problematic. You won't see any visible gas or notice any strange odors when CO is leaking into your home. And by the time you or your family members start to notice physical symptoms, there may have already been damage done to your health, even if you immediately exit the property.

Health Hazards

Exposure to CO can cause major health problems and can even be fatal in some cases. For these reasons, having properly working carbon monoxide detectors in your household is a must, especially if you use a gas-powered furnace.

During a furnace safety inspection, your hired technician should always verify that your CO detectors are working. While you can never guarantee that your furnace won't experience a problem, you should at least make sure that you know if noxious CO is leaking into your living space.

Schedule Yearly Furnace Inspections

It can be easy to procrastinate when it comes to scheduling furnace safety and heating inspections. If you wait until temperatures drop to have someone come out and inspect your furnace, you could end up waiting a day or two to get it repaired. When it gets down to below-freezing temperatures, heating, and cooling companies become overwhelmed with service calls. It's much better to be proactive. You aren't doing yourself or your family any favors by putting them off for too long.

By having qualified HVAC technicians closely examine your heating system each year, you can create a safer home environment, reduce energy costs, and improve your comfort. Ultimately, there's no downside, but there are major benefits to be had.