Explore the Different Types of Ductwork

A Comprehensive Guide for Efficient HVAC Systems

When it comes to ensuring efficient airflow in your HVAC system, the types of ductwork you choose are critical. Are you opting for the durability of rigid ducts, the versatility of flexible ducts, or the balance of semi-rigid ducts? Make an informed choice by understanding the distinctions between these key options, which affect everything from installation challenges to long-term energy efficiency. This guide will walk you through the different types of ductwork to help you optimize your system’s performance.

Key Takeaways

HVAC ductwork varieties, specifically flexible, rigid, and semi-rigid ducts, are critical in home comfort and efficiency, with each type offering unique properties and applications for different space constraints and durability requirements.

Material choice in ductwork construction, such as galvanized steel, fiberglass lining, or fiberboard, significantly affects HVAC performance, energy efficiency, and indoor air quality, necessitating careful consideration of the benefits and potential drawbacks of each material.

Proper installation and regular maintenance of ductwork are essential for ensuring optimal performance and longevity of HVAC systems, with professional interventions needed to address issues like energy loss, temperature inconsistencies, unusual noises, and indoor air quality degradation.

Diving into Ductwork: Understanding the Varieties

HVAC ductwork may seem simple, but it’s a complex maze designed to deliver comfort to every corner of your home. It comes in different shapes and sizes, each with its unique properties and applications. The three main categories of HVAC ductwork, or types of air ducts, are flexible, rigid, and semi-rigid ducts. Each of these has a critical role in shaping your home’s comfort and efficiency.

Flexible ductwork, as the name suggests, is the contortionist of the HVAC world. It can twist and turn, making it perfect for navigating through tight spaces and complex layouts. On the other hand, rigid ducts are the stalwarts, known for their durability and lower risk of leaks. In the middle, we have semi-rigid ducts, which bring the best of both worlds. To understand them better, let’s delve deeper into each type.

Sheet Metal Ductwork Explained

Ever wondered why the HVAC professionals often recommend sheet metal ducts? It’s because they are the iron men of the ductwork world. Constructed from galvanized steel or aluminum, these ducts are highly durable and rust-resistant. They’re often used in residential properties, making them a common sight in many homes.

What sets sheet metal ducts apart is:

Their smooth surface, which prevents the accumulation of dirt and dust, simplifying maintenance

This smoothness is also a nightmare for mold and bacteria, as it leaves them with no place to grow

This contributes to a cleaner air distribution system, ensuring that every breath you take is fresh and clean.

Flexible Ducts: The Solution for Tight Spaces

When it comes to navigating tight or awkward spaces, flexible ducts are your best bet. These ducts are like gymnasts, bending and twisting to fit into spaces where other duct types would struggle. This makes them a valuable solution for space-constrained layouts, such as in older homes or buildings with complex designs.

Despite their flexibility, these ducts require careful handling. They can be less durable than other types, and are more susceptible to punctures. If not installed properly, they can lead to reduced efficiency. That’s why it’s crucial to ensure proper installation, which includes careful support to prevent sagging and avoid kinks and bends that can impair airflow.

Rigid Ductwork: The Strong and Customizable Choice

Now, let’s turn to the strong and sturdy rigid ducts. Made from materials such as galvanized steel or aluminum, these ducts are valued for their durability and non-porous attributes. This makes them a strong choice for HVAC systems that need to withstand the test of time.

Rigid ducts are the champions of efficiency, thanks to their smooth surfaces and straight design. However, they do come with challenges. Their heavier structure requires precise fitting, which can make their installation more difficult. Moreover, their materials come with a higher cost implication compared to those used for flexible ducts.

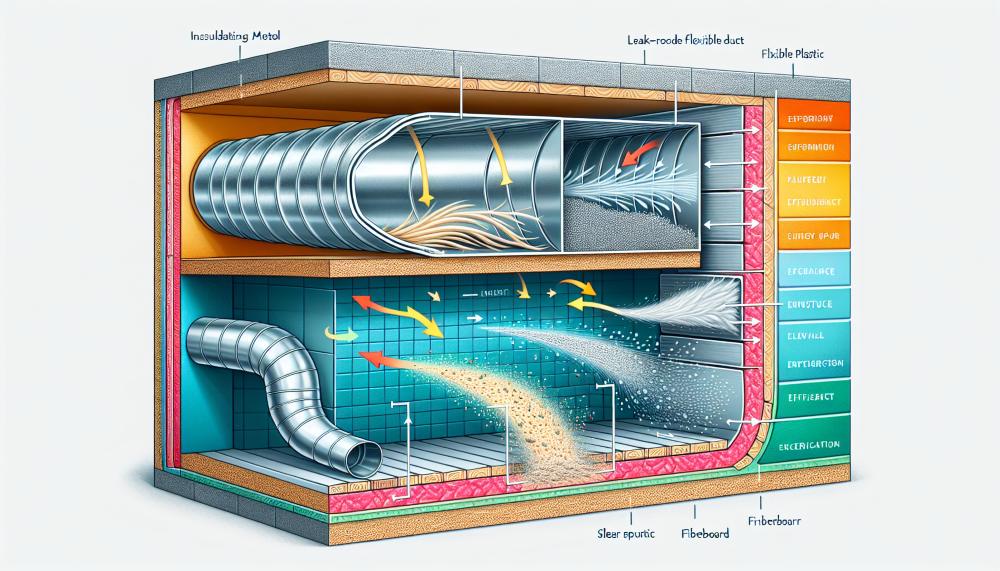

The Role of Materials in Ductwork Performance

By now, you’re familiar with the different types of ductwork. But did you know that the material of the ductwork also plays a crucial role in your HVAC system’s performance? From energy efficiency to indoor air quality, the duct material can significantly impact your home’s comfort and energy bills.

For instance, the non-porous nature of sheet metal ducts inhibits the growth of mold and bacteria, thereby enhancing indoor air quality. On the other hand, fiberboard ducts, with their high insulation value, are effective in maintaining temperatures within HVAC systems, making them ideal for energy efficiency.

Let’s dive into the world of duct materials and discover their unique characteristics and benefits.

Galvanized Steel: A Popular and Reliable Option

Galvanized steel is often the first choice for ductwork due to its durability and robustness. It’s like the superhero of duct materials, always ready to withstand the challenges of time and use.

But what truly sets galvanized steel apart is the galvanization process. This process enhances the steel’s integrity and provides resistance to red rust, although it can still be susceptible to white rust if exposed to moisture. Moreover, its non-porous surface helps protect air ducts from contaminants, contributing to better indoor air quality.

Fiberglass Lined Ducts: Balancing Insulation and Sound Dampening

Imagine a duct that not only conserves energy but also keeps your home quiet. That’s exactly what fiberglass lined ducts offer. Similar to sheet metal ducts, these ducts feature a fiberglass lining that serves to limit heat loss and reduce sound from the HVAC system, making them a popular choice in environments where noise reduction is desirable.

Despite their benefits, fiberglass lined air ducts can be prone to mold contamination and requires thorough cleaning to prevent such issues. More importantly, cleaning older fiberglass lined ducts carries a risk of releasing fiberglass particles into the air, which can detrimentally affect indoor air quality. Therefore, it’s crucial to balance the energy efficiency and acoustical benefits provided by fiberglass lined ductwork with the potential health implications of mold and fiberglass particle contamination.

Fiberboard Air Ducts: Insulation and Cost Efficiency

For those looking for cost-effective and insulated ducts, fiberboard air ducts might be the perfect solution. These ducts consist of compressed resin-bonded fiberglass, offering good insulation value and effectively maintaining temperatures within HVAC systems.

Despite their insulating benefits, fiberboard ducts are prone to the growth of mold and bacteria, especially in humid climates or settings where moisture is present. Older fiberboard ducts that lack modern mold or mildew prevention treatments should be inspected and replaced promptly to ensure they are adequately sealed against the release of fiberglass particles. In contrast, fiberglass ducts can provide a more resistant alternative to these issues.

Installation Insights: Maximizing Your HVAC Ductwork's Potential

Installing ductwork is not just about connecting the pieces; it’s an art that requires precision and knowledge. From sizing the ducts correctly to placing them in the right locations, every detail matters in ensuring optimal HVAC system performance.

Proper ductwork installation can lead to more consistent comfort by designing duct systems that evenly distribute conditioned air and eliminate uneven temperatures in the home. Moreover, using longer sections of ductwork with fewer seams can greatly reduce the chances of air leakage, leading to greater energy efficiency.

Achieving Airtight Seals and Proper Insulation

Sealing and insulating your ductwork could be the key to unlocking your HVAC system’s full potential. Here are the benefits of sealing and insulating your ductwork:

Airtight seals prevent conditioned air from escaping the ducts

Proper insulation reduces heat loss

Enhances energy efficiency

Reduces noise

But how do you achieve this? HVAC professionals achieve this by:

Using screws to attach duct sections

Sealing joints and seams with fiberglass mesh and mastic

Testing for duct tightness to ensure that conditioned air does not escape through seams, preventing energy consumption from rising due to the HVAC system overworking to maintain the desired temperature.

Navigating Tight Corners with Flex Ducts

Installing flex ducts is like solving a puzzle. You need to:

Navigate tight corners

Ensure that the ducts are not squeezed into cavities smaller than their outer diameter

Bends should have a radius at least equal to the duct’s diameter to prevent compression and maintain proper airflow.

It’s also crucial to install the flex ducts straight, pull them taut, and properly support them according to code. This prevents sagging, kinks, or punctures that can lead to decreased airflow and system efficiency.

Ensuring Rigid Duct Integrity

Ensuring the integrity of rigid ductwork is all about precision and attention to detail. Due to their heavier structure, they need to be precisely fitted and securely attached to prevent leaks and maintain efficient airflow.

Using longer pieces of ductwork with as few connecting pieces as possible helps maintain the integrity of rigid ducts and minimize air leakage. Additionally, proper sizing and secure attachment during professional installation can reduce the strain on HVAC systems, prolonging their lifespan and reducing operational noise.

Indicators of Ductwork Health: Recognizing When Maintenance Is Needed

Your ductwork may be out of sight, but it should never be out of mind. Regular check-ups and maintenance are essential for its health and longevity. But how do you know when your ductwork needs attention? There are several signs, including fluctuating energy consumption, temperature variances, and unusual noises, that can signal inefficiencies or problems within the system.

Ignoring these signs could lead to serious issues, such as fiber release into the airstream from deteriorating fiberglass duct liners or emission of dust or debris upon HVAC system startup. These issues not only degrade indoor air quality but can also lead to respiratory problems.

Fluctuating Energy Consumption

Have you noticed your energy bills creeping up for no apparent reason? The culprit could be your ductwork. Leaky ductwork can cause a 20-40% loss in heating and cooling energy, leading to inflated utility bills.

Particularly, in commercial buildings, flexible ducts are more susceptible to broken seals and connections, aggravating energy losses. Insulating supply ducts and ensuring they are well-sealed, especially in unconditioned spaces, can significantly mitigate heat loss and enhance energy efficiency.

Variance in Room Temperatures

Is your living room warm and cozy while your bedroom feels like a freezer? This could be due to improperly designed ductwork that’s not appropriately sized for each room. Larger rooms require more time to adjust to desired temperatures and may exhibit temperature differences if the ductwork to these spaces is not correctly calculated.

Blocked or covered vents can also lead to temperature variances. They can significantly restrict the flow of conditioned air, making a room feel too cold. Regular checks and professional inspection can help identify these issues and ensure a comfortable living environment.

Unusual Noises from the Duct System

Unusual noises from your duct system can be more than just annoying; they can signal underlying issues within your HVAC system. Banging and popping sounds typically result from the ductwork’s metal expanding and contracting due to changes in internal temperatures. At the same time, rattling noises often indicate loose components, such as metal seals or connections that have failed or come undone.

Booming sounds may signal a lack of sufficient dampers or expansion joints at the point where the duct’s plenum and main trunk meet. Meanwhile, scratching noises suggest the presence of animals like squirrels or rats inside the ducts. If you notice any of these noises, it’s time to call in the professionals for a thorough inspection and necessary repairs.

Enhancing Indoor Comfort: The Impact of Ductwork on Air Quality

A comfortable home is not just about the right temperature; it’s also about fresh, clean air. Your ductwork plays a crucial role in maintaining good indoor air quality. For instance, galvanized steel ducts, with their non-porous surface, inhibit mold growth and prevent bacteria buildup, leading to enhanced indoor air quality.

However, without regular maintenance, ducts can accumulate dust, dirt, and allergens, degrading indoor air quality and leading to respiratory issues. Materials like fiberglass can also deteriorate over time, releasing particles into the air. Regularly cleaning air ducts significantly improves air quality by removing these accumulated contaminants, thus safeguarding health within indoor environments.

Professional Care for Your Ductwork

Your HVAC ductwork, also known as air duct systems, is a vital component of your home comfort system, including your air conditioning and air conditioner, and like any other component, it needs professional care to function optimally. Regular inspections and maintenance can prevent health risks and maintain in-home comfort.

Professional maintenance is crucial in mitigating temperature inconsistencies caused by HVAC system malfunctions. Moreover, professionally installed ductwork can lead to quieter operation by rectifying airflow problems and ensuring the ducts are accurately sized, optimally sealed, and securely installed. So, whether you’re planning a new installation, repair, or an upgrade, always opt for professional HVAC services for the best results.

Summary

Your home’s comfort relies heavily on the unsung hero - HVAC ductwork. From the type of ductwork - be it flexible, rigid, or semi-rigid - to the material used and the quality of installation, every aspect can impact your home’s energy efficiency, air quality, and overall comfort. Regular maintenance and professional care are essential to ensure the longevity and optimal performance of your ductwork. After all, your home is your sanctuary, and you deserve the highest level of comfort.

Frequently Asked Questions

What are the three types of ductwork?

The three types of ductwork are flexible ductwork, rigid ductwork, and semi-rigid ductwork. Each type has its own best use cases and benefits. Flexible, rigid, and semi-rigid ducts are typically used within ventilation systems for various purposes.

What is the best type of air ductwork?

The best type of air ductwork for ventilation is semi-rigid ductwork, as it does not leak air when installed properly, ensuring maximum HVAC efficiency.

What is the most common type of duct?

The most common type of duct is sheet metal air ducts, which are usually made of galvanized steel or aluminum. These ducts come in various shapes such as round, rectangular, or spiral oval.

How do different duct materials impact HVAC system performance?

Choosing the right duct material can significantly impact your HVAC system's performance, energy efficiency, and indoor air quality. For example, galvanized steel ducts can inhibit mold growth, while fiberboard ducts provide good insulation value.

What signs indicate that my ductwork needs maintenance?

Signs that indicate your ductwork needs maintenance include fluctuating energy consumption, temperature variances in different rooms, and unusual noises from the duct system. These can indicate inefficiencies or problems within your ductwork.